- Via Reccagni 15/b, Castel Mella (BS) 25030 Italy

- +39 030 25 59 291

- info@avogadroenergy.com

Water tube boiler

Testing: Compliant with PED, ASME, or EAC directives.

GENERAL DESCRIPTION OF THE WATER TUBE BOILER

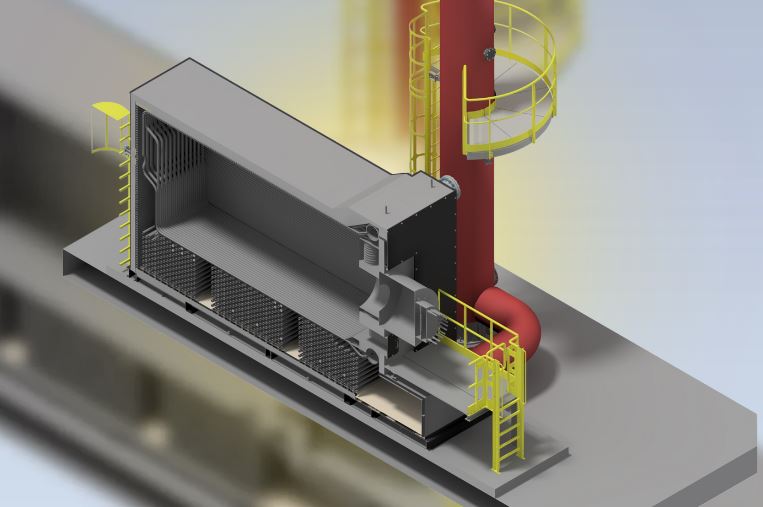

The water tube boiler features a parallelepiped-shaped "D" combustion chamber, fully shielded on all six sides by tangent tubes. These tubes are welded to upper and lower headers. The external tubes, tangent to each other, are enclosed by a sealed metal framework made of small panels that allow free expansion without cracking. Combustion gases exiting the furnace are diverted to a tube bundle located on the side of the furnace, arranged in multiple rows and welded to cylindrical bodies, forming a convection bank.

This design enables operation with pressurized fuel (pressurized combustion) and precise control of combustion air, ensuring high efficiency at all loads. The exterior is insulated with high-density mineral wool mats to minimize heat loss, and the entire structure is covered with removable corrugated sheet metal panels for easy inspection.

The tube bundle consists of numerous vertical tubes arranged in multiple rows, designed to absorb heat from combustion gases via convection. The tube layout allows for easy cleaning and inspection, with access doors at the ends and drain tubes for soot removal.

The boiler is mounted on a base that allows free expansion and includes a low-water safety device that automatically shuts off the burner if the water level falls below the safety limit. The generator is designed for easy transport on a special roadworthy trailer.

PRECISE DESIGN AND EXECUTION

The boiler's design is based on extensive experience, ensuring safe and durable systems. Pressure vessels are tested according to PED regulations. Manufactured in-house by highly skilled personnel, the boiler guarantees safety and high quality.

Technical Details of the Boiler Body:

-

Upper cylindrical body: Carbon steel sheet with hot-formed elliptical heads, automatically welded and radiographically tested.

-

Lower cylindrical body: Carbon steel sheet with hot-formed elliptical heads.

-

Inspection manholes for internal access.

-

Side shielding tubes and convection bundle tubes: High-quality steel, arranged tangentially and welded to the bodies.

ECONOMIZER

The economizer recovers sensible heat from the flue gases exiting the boiler and preheats the feedwater before it enters the boiler. It features a horizontal finned tube bundle located outside the boiler body, with vertical flue gas flow and manual ash removal from the bottom hopper.

CONSTRUCTION MATERIALS

-

Upper cylindrical body: ASTM A537 or equivalent.

-

Lower cylindrical body: ASTM A537 or equivalent.

-

Wall tubes: C14 Uni 5462 or equivalent.

-

Bundle tubes: C14 Uni 5462 or equivalent.

-

Flanges: ASTM A105.

REGULATION, CONTROL, AND SAFETY EQUIPMENT

Regulation:

-

Pressure transducers, 3-element level control systems (level, water flow, and steam flow), and electronic controllers with PLC.

Control:

-

Pressure gauges, level indicators, and transmitters for pressure and level monitoring.

Safety:

-

High-pressure steam safety switches (PED certified), safety valves, and level switches for high and low water protection.

FEEDWATER SYSTEM

Modulating execution with multistage centrifugal pumps, shut-off valves, and stainless steel check valves. Ensures proper feedwater supply for boiler operation.

VALVING SYSTEM

Includes steam and boiler shut-off valves, blowdown and drain valves, and sample and reagent injection valves.

ELECTRICAL CONTROL PANEL

The system includes an electrical control panel with a PLC for boiler and burner regulation, safety switches, protective fuses, and visual indicators for system operation.

COMBUSTION SYSTEM

Designed to minimize pollutant emissions, the system features a modulating natural gas burner with electronic regulation. Power modulation is managed by a servomotor controlling combustion air dampers and fuel flow. Control is achieved via thermoregulators with signal feedback.

MAXIMUM EFFICIENCY LEVELS

Water tube boilers are designed for maximum efficiency thanks to:

-

Economizer: Preheats feedwater using exhaust gases, achieving up to 95% efficiency.

-

Combustion Air Preheater: Uses exhaust gases from the economizer, increasing thermal efficiency to 97%.

DATASHEET

| MODEL | STEAM OUTPUT (KG/H) | BOILER POWER (KW) | DIMENSIONS (MM) | CAPACITY (LITERS) |

|---|---|---|---|---|

| WT-650 | 6,500 | 4,550 | 4,300 x 3,100 x 3,600 | 7,100 |

| WT-800 | 8,000 | 5,900 | 4,500 x 3,200 x 3,700 | 8,000 |

| WT-1000 | 10,000 | 7,000 | 4,700 x 3,500 x 3,900 | 9,300 |

| WT-1200 | 12,000 | 8,400 | 5,300 x 3,500 x 4,000 | 10,600 |

| WT-1500 | 15,000 | 10,500 | 6,400 x 3,500 x 4,100 | 11,100 |

| WT-1800 | 18,000 | 12,600 | 6,600 x 3,800 x 4,100 | 12,900 |

| WT-2000 | 20,000 | 14,000 | 7,200 x 3,800 x 4,100 | 14,650 |

| WT-2500 | 25,000 | 17,500 | 8,500 x 4,000 x 4,100 | 15,300 |

| WT-3000 | 30,000 | 21,000 | 9,300 x 4,000 x 4,200 | 17,650 |

| WT-3500 | 35,000 | 24,500 | 9,700 x 4,300 x 4,200 | 19,200 |

| WT-4000 | 40,000 | 28,000 | 10,500 x 4,300 x 4,500 | 20,000 |

| WT-5000 | 50,000 | 35,000 | 12,000 x 4,300 x 4,500 | 25,000 |

TYPICAL COMPLETE SUPPLY

-

Electrical control panel: Equipped with PLC and onboard instrumentation for regulation, control, and safety.

-

Modulating feedwater system: Includes multistage centrifugal pump, valves, and accessories.

-

Gas and/or diesel burner: Modular and low NOx, with electrical panel.

-

Support and service structure: Includes ladders and walkways for inspection.

-

Discharge piping: Includes valves and blowdown tank.

-

Testing: Compliant with PED, ASME, or EAC directives.

Water tube boilers are the ideal choice for robust, highly efficient, and versatile steam production in large industrial plants.