Thermal Oil Boilers – OH Model

The OH series consists of thermal oil heaters built with concentric helical coils, featuring one or more passes and a three-pass smoke tube design.

The heated thermal oil can be used both as a direct heating fluid and as a heat transfer medium for the indirect production of steam, superheated water, etc. These generators can accommodate any market-available burner.

Available accessories: oil circulation pump, oil filling pump, expansion vessel, oil collection vessel, evaporator, three-way control valve…

Key Features:

- Operating temperatures up to 300°C (up to 400°C on request)

- Power range from 50 kW to 15,000 kW

- Available in horizontal and vertical configurations

- Operate without pressure, exempting the need for a certified boiler operator

- Capability to produce steam or superheated water without requiring a licensed operator

- Fully automated control instrumentation

- High-efficiency version available with air preheater

Operating Schematics

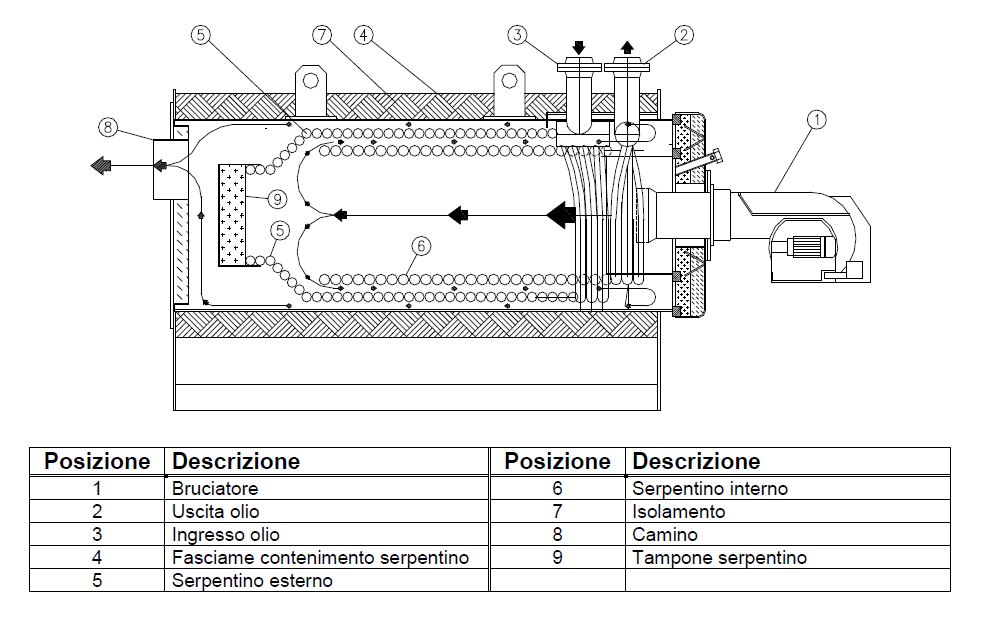

- Horizontal OH Model (OH-H):

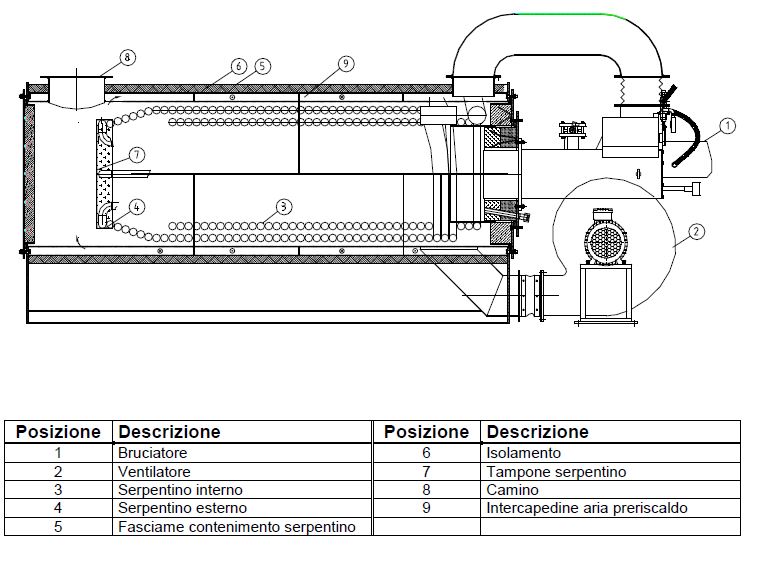

- High-efficiency Horizontal Version (OH-H-R):

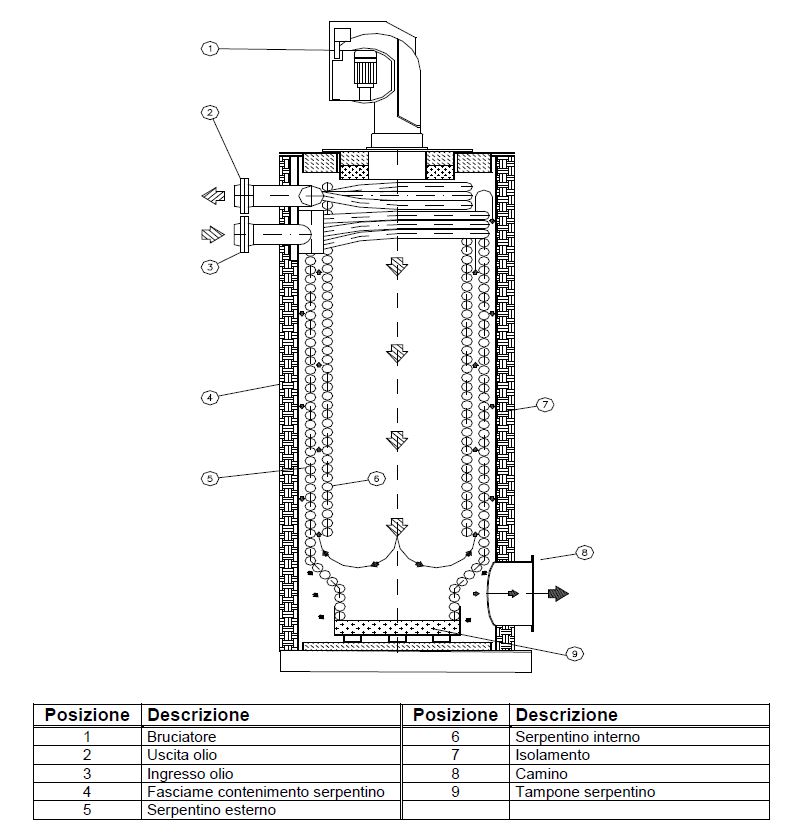

- Vertical OH Model (OH-V):

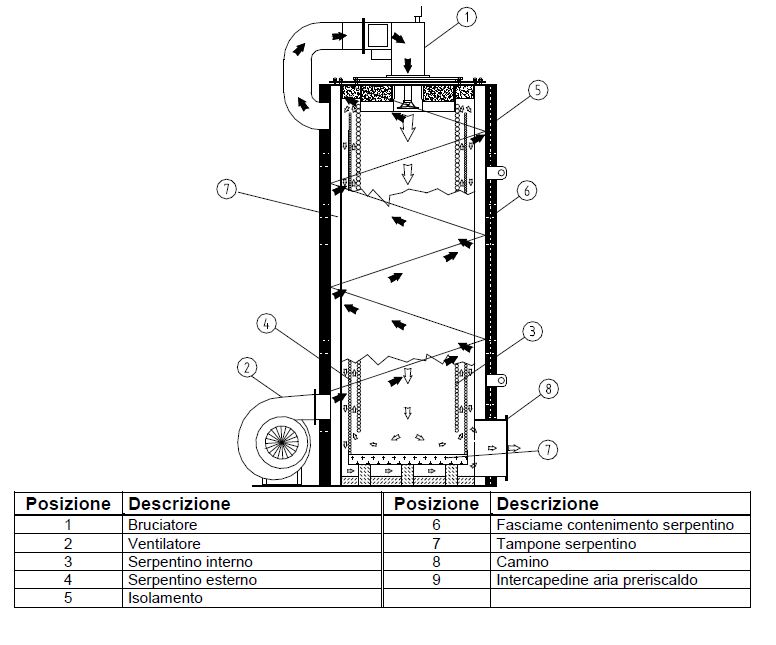

- High-efficiency Vertical Version (OH-V-R):

Ultra-Low NOx Emission Thermal Oil Heaters

Available with power outputs from 75 kW to 15,000 kW, design temperatures up to 350°C, and operating pressures of 10 bar.

Boiler Body Structure

Our heaters feature a multi-stage tube bundle heating system, constructed from high-quality ASTM A 106 Gr.B steel, with flanged collectors and temperature sensor ports. The thick-walled cylindrical casing is reinforced and insulated with mineral rock wool, covered with polished aluminum sheet, ensuring high thermal efficiency and durability.